Shengda Ceramic provides all kinds of aluminum nitride ceramics and engineering ceramics.

Product Introduction

Product Overview

Our aluminum nitride-boron nitride (AlN-BN) composite ceramic insulation boards represent the cutting edge in high-temperature thermal management materials. Engineered for extreme thermal environments, these advanced ceramic boards combine the exceptional thermal conductivity of aluminum nitride with the superior lubricity and thermal shock resistance of boron nitride - delivering unparalleled performance in demanding applications.

Key Product Advantages

1. Ultra-High Thermal Conductivity (90-180 W/m·K) with electrical insulation

2. Exceptional Thermal Shock Resistance - withstands rapid temperature cycling

3. Low Thermal Expansion (4.5-5.5 ×10⁻⁶/°C) for dimensional stability

4. High Temperature Capability up to 1800°C in inert atmospheres

5. Machinable - can be precision-cut to complex shapes

6. Chemical Inertness - resistant to molten metals and corrosive gases

Industry Applications

✔ Semiconductor Manufacturing

✔ Metal Processing

✔ Aerospace & Defense

✔ Energy & Power Generation

✔ Advanced Research

|  |  |

Why Choose Our Ceramic Products?

✅ Factory Direct Pricing - Eliminate middleman markups

✅ ISO-Certified Manufacturing - Consistent quality assurance

✅ Rapid Prototyping - 2-3 week lead time for samples

✅ Technical Expertise - 30+ years in advanced ceramics

✅ Global Logistics - Reliable worldwide shipping

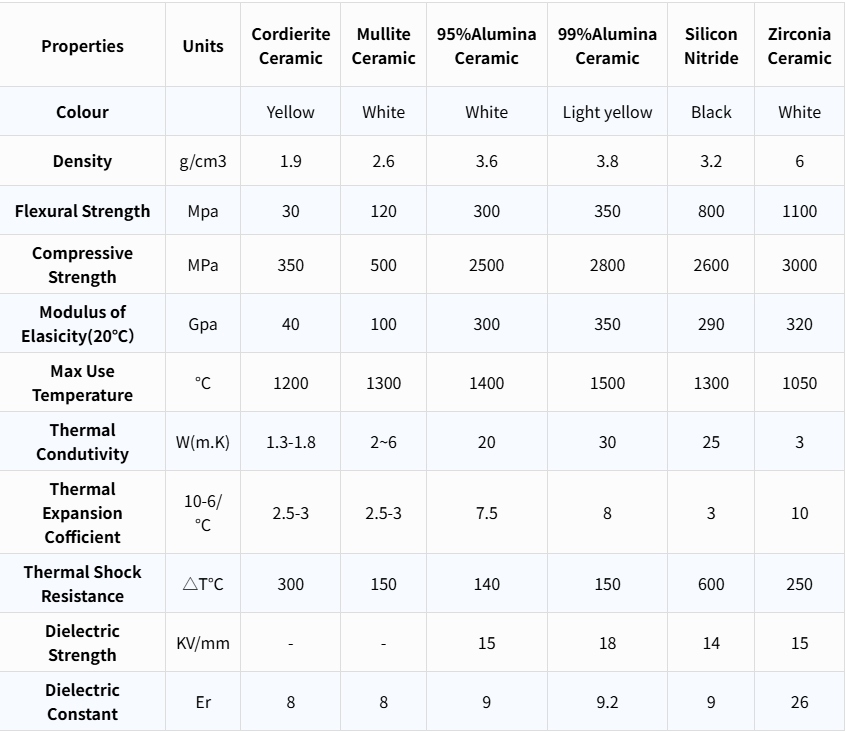

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Packaging and shipping

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory established in 1995 with more than 22 years of OEM and international trade experience.

Q: Do you provide customized service?

A: Yes, we have a professional team which has rich experience in industrial ceramics,so we'll try to satisfy your requirement.

Q:How long is the production cycle?

A: 10-30 days depends on your purchasing quantity.

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Customize Aluminum Nitride Composite Boron Nitride Ceramic Insulation Board

If you have any questions or need help, feel free to contact with our team.

Phone

+86 15335210683

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By