► Place of Origin: Jiangsu, China

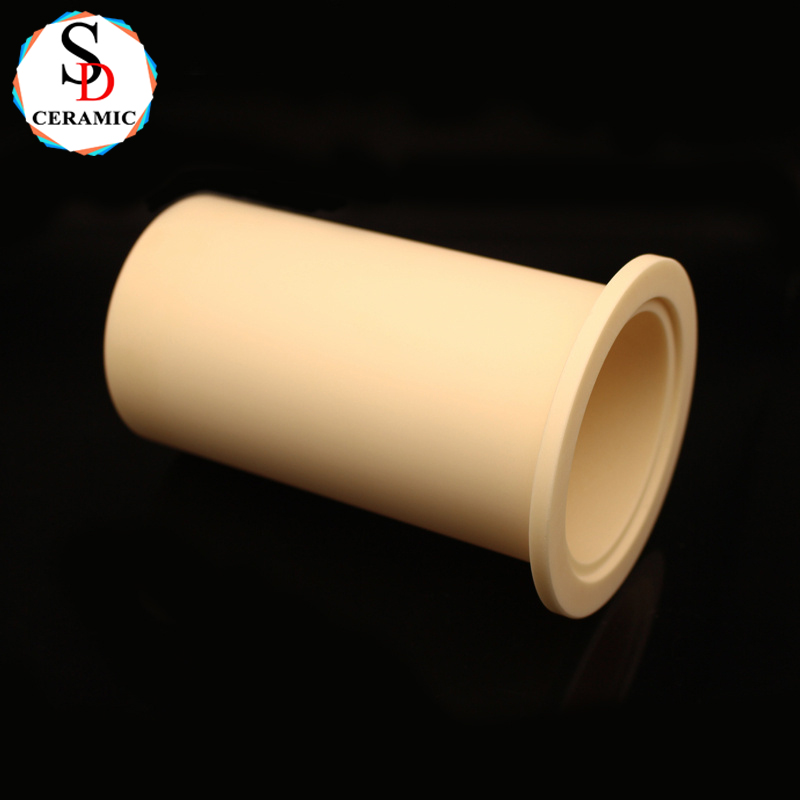

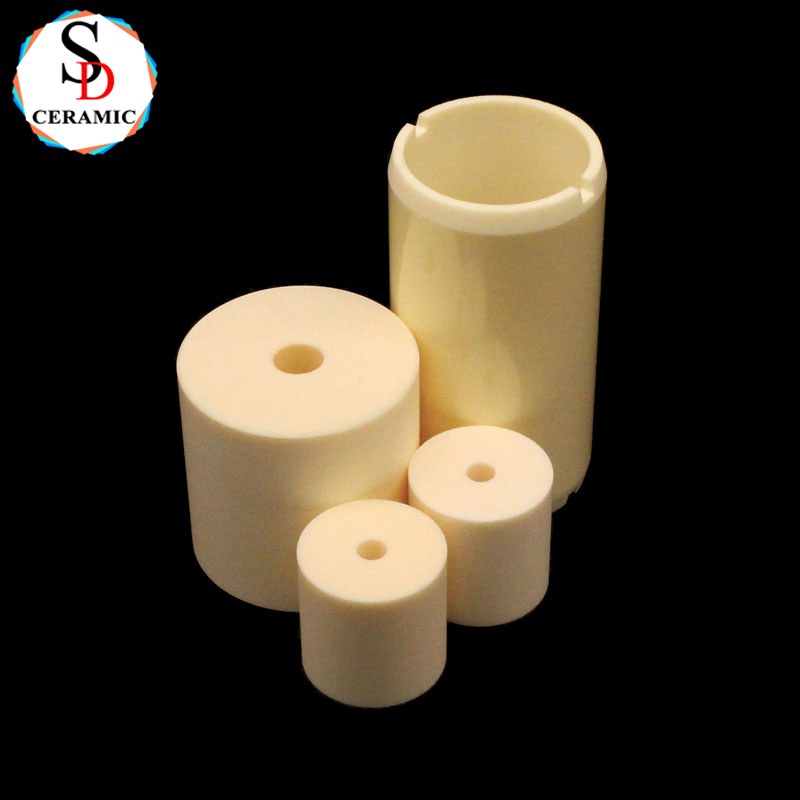

► Material: 99% alumina ceramic

► Density: 3.9g/cm³

► Max use temperature: 1600℃

► Contract Manufacturing: OEM Service Offered

Product Introduction

Our 99% alumina ceramic crucibles represent the gold standard in high-temperature laboratory equipment, offering exceptional thermal stability, chemical purity, and mechanical durability for the most demanding research and industrial processes. Engineered for precision and reliability, these crucibles maintain structural integrity at temperatures up to 1750°C (3182°F) while resisting thermal shock and chemical attack.

| Key Product Advantages | Industry Applications | ||

▸ Ultra-High Purity ▸ Extreme Temperature Resistance ▸ Superior Thermal Shock Resistance ▸ Chemical Inertness ▸ Low Thermal Conductivity ▸ Custom Configurations | ▸ Materials Research & Development ▸ Chemical Analysis ▸ Semiconductor Manufacturing ▸ Glass & Ceramic Industries ▸ Energy & Battery Research |

Why Choose Our Ceramic Products?

✔ Factory Direct Pricing - Eliminate middleman markups

✔ ISO-Certified Manufacturing - Consistent quality assurance

✔ Rapid Prototyping - 2-3 week lead time for samples

✔ Technical Expertise - 30+ years in advanced ceramics

✔ Global Logistics - Reliable worldwide shipping

|  |  |

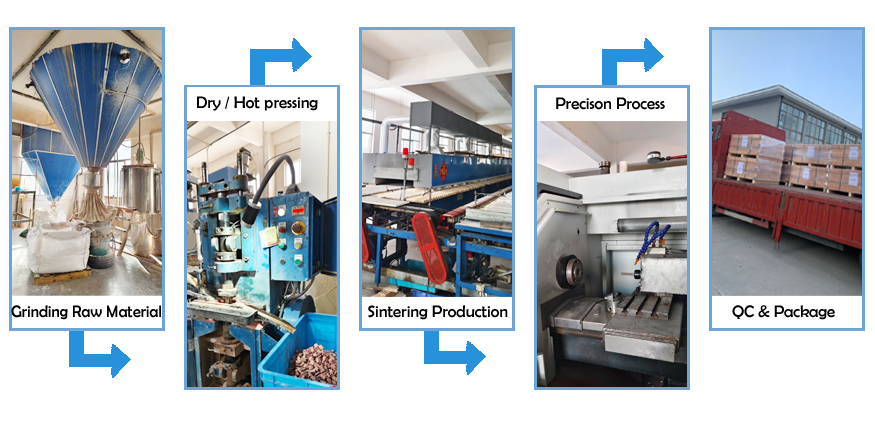

Production Process

1. Grind and crush the raw materials to be slurry or powder.

2. se-different method to making the slurry or powder into semi-finished products.

3. Put the semi-finished products into the kiln for dewaxing and sintering.

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery.

|

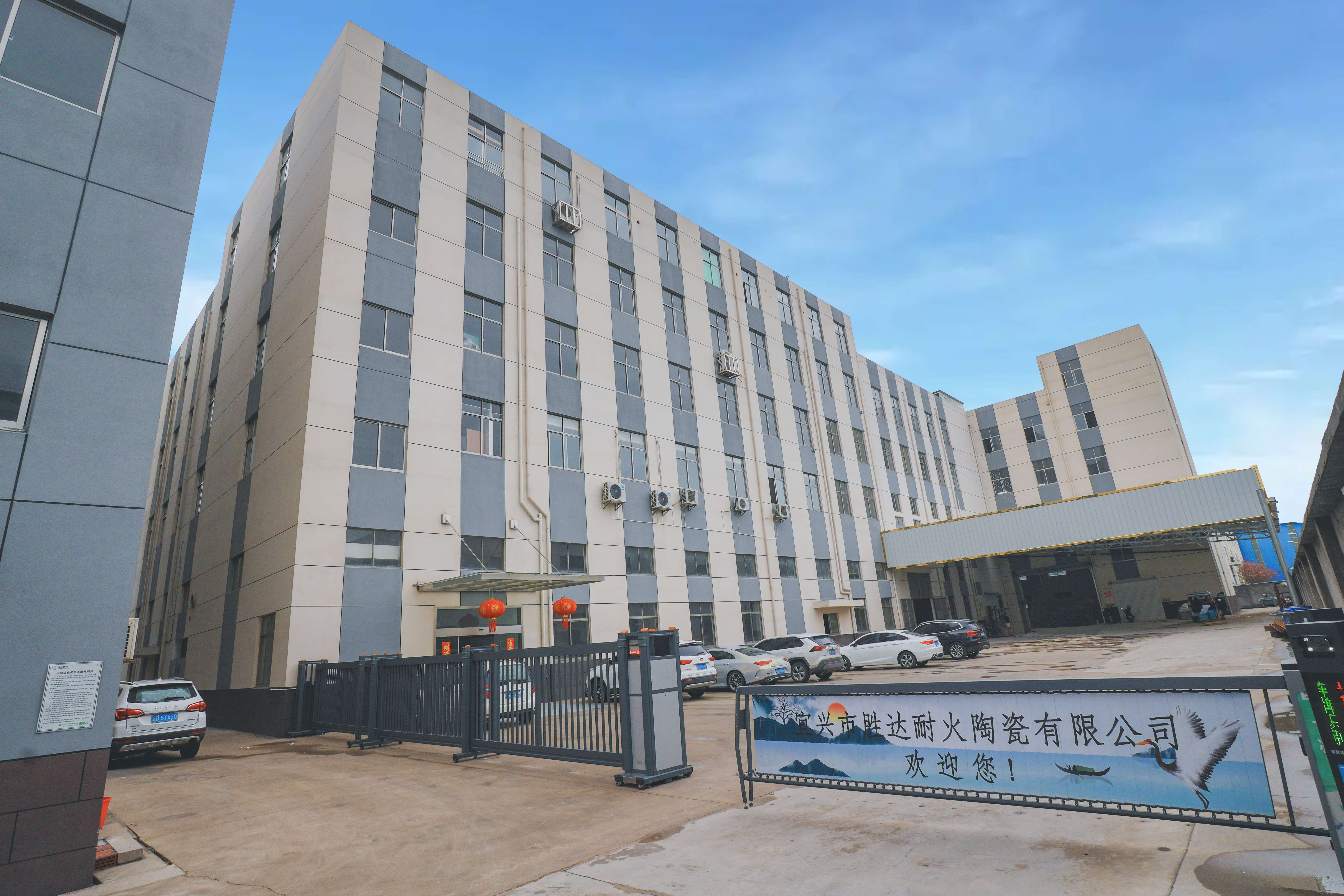

Company

| Yixing Shengda Refractory Ceramic Co, Ltd. was established in Yixing City, China in 1995, witha production area of over 10,000㎡. lt is an enterprise specializing in the production of alumina ceramic,zirconia ceramic,slicon nitride, silicon carbide and other precision ceramic products. And we also produce ceramic band heaters, ceramic terminal block, cordierite and mullite ceramic parts an other ceramic products. |

Certifications

Technical Parameters

| Properties | Units | Cordierite Ceramic | Mullite Ceramic | 95%Alumina Ceramic | 99%Alumina Ceramic | Silicon Nitride | Zirconia Ceramic |

| Colour | Yellow | White | White | Light yellow | Black | White | |

| Density | g/cm3 | 1.9 | 2.6 | 3.6 | 3.8 | 3.2 | 6 |

| Flexural Strength | Mpa | 30 | 120 | 300 | 350 | 800 | 1100 |

| Compressive Strength | MPa | 350 | 500 | 2500 | 2800 | 2600 | 3000 |

| Modulus of Elasicity(20℃) | Gpa | 40 | 100 | 300 | 350 | 290 | 320 |

| Max Use Temperature | °C | 1200 | 1300 | 1400 | 1500 | 1300 | 1050 |

| Thermal Condutivity | W(m.K) | 1.3-1.8 | 2~6 | 20 | 30 | 25 | 3 |

| Thermal Expansion Cofficient | 10-6/°C | 2.5-3 | 2.5-3 | 7.5 | 8 | 3 | 10 |

| Thermal Shock Resistance | △T℃ | 300 | 150 | 140 | 150 | 600 | 250 |

| Dielectric Strength | KV/mm | - | - | 15 | 18 | 14 | 15 |

| Dielectric Constant | Er | 8 | 8 | 9 | 9.2 | 9 | 26 |

FAQ

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : High Heat Resistant Alumina Products 99% Alumina Crucible Ceramic For Laboratory

If you have any questions or need help, feel free to contact with our team.

Phone

+86 15335210683

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By