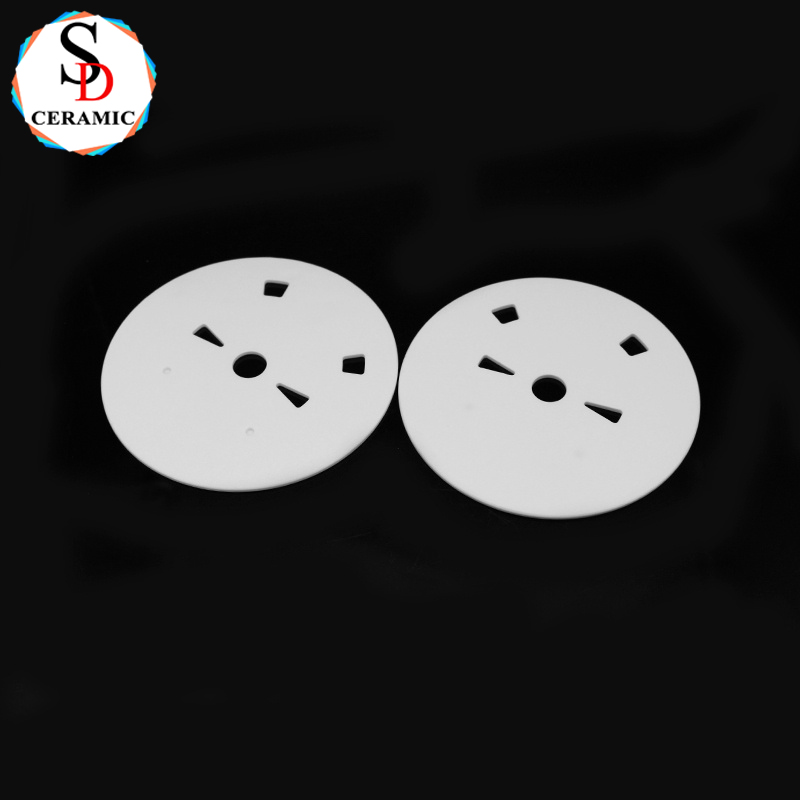

Shengda Ceramic delivers ultra-durable ceramic disc with exceptional heat and wear resistance, perfect for demanding industrial applications. Custom sizes available—contact us now for high-performance solutions!

Product Introduction

Product Overview

Our 95% alumina ceramic discs represent the perfect balance between performance and cost-effectiveness for industrial applications requiring exceptional wear resistance, electrical insulation, and thermal stability. These precision-engineered Al₂O₃ components deliver superior mechanical properties and reliable performance in the most challenging environments.

Key Product Advantages

1. High Wear Resistance - Mohs hardness of 8.5 for extended service life

2. Excellent Electrical Insulation - Volume resistivity >10¹⁴ Ω·cm

3. Thermal Stability - Withstands temperatures up to 1500°C (2732°F)

4. Chemical Inertness - Resists acids, alkalis and corrosive materials

5. Cost-Effective Performance - Optimal price-to-performance ratio

6. Precision Manufacturing - Tight tolerances (±0.1mm available)

Industry Applications

✔ Electronics & Semiconductor

✔ Industrial Machinery

✔ Automotive & Aerospace

✔ Medical Equipment

✔ Energy & Power Generation

|  |  |

Why Choose Our Ceramic Products?

✅ Factory Direct Pricing - Eliminate middleman markups

✅ ISO-Certified Manufacturing - Consistent quality assurance

✅ Rapid Prototyping - 2-3 week lead time for samples

✅ Technical Expertise - 30+ years in advanced ceramics

✅ Global Logistics - Reliable worldwide shipping

Technical Parameters

| Ceramic Properties | |||||||

| Properties | Units | Cordierite Ceramic | Mullite Ceramic | 95%Alumina Ceramic | 99%Alumina Ceramic | Silicon Nitride | Zirconia Ceramic |

| Colour | Yellow | White | White | Light yellow | Black | White | |

| Density | g/cm3 | 1.9 | 2.6 | 3.6 | 3.8 | 3.2 | 6 |

| Flexural Strength | Mpa | 30 | 120 | 300 | 350 | 800 | 1100 |

| Compressive Strength | MPa | 350 | 500 | 2500 | 2800 | 2600 | 3000 |

| Modulus of Elasicity(20℃) | Gpa | 40 | 100 | 300 | 350 | 290 | 320 |

| Max Use Temperature | °C | 1200 | 1300 | 1400 | 1500 | 1300 | 1050 |

| Thermal Condutivity | W(m.K) | 1.3-1.8 | 2~6 | 20 | 30 | 25 | 3 |

| Thermal Expansion Cofficient | 10-6/°C | 2.5-3 | 2.5-3 | 7.5 | 8 | 3 | 10 |

| Thermal Shock Resistance | △T℃ | 300 | 150 | 140 | 150 | 600 | 250 |

| Dielectric Strength | KV/mm | - | - | 15 | 18 | 14 | 15 |

| Dielectric Constant | Er | 8 | 8 | 9 | 9.2 | 9 | 26 |

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : High Precision 95% Alumina Ceramic Disc Al2O3 Ceramic Part

If you have any questions or need help, feel free to contact with our team.

Phone

+86 15335210683

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By